Falling number is both a procedure (1) and an instrument (Perten, Huddinge, Sweden) that is used to gauge the activity level of endogenous alpha-amylase in small grains such as wheat. The operation involves bringing a meal–water or flour–water mixture contained in a test tube to boiling temperature as the starch within the endosperm gelatinizes and undergoes enzymatic hydrolysis. The time (s) needed for a stirrer of precise geometry to agitate and fall by its own weight through the heated and hydrolyzed paste is defined as the “falling number.” Thin (low viscosity, hence low falling number) pastes indicate elevated alpha-amylase activity. Generally, to the processor, wheat with elevated alpha-amylase is undesirable. Thus, wheat lots possessing falling numbers below an established value, typically 300 s in the United States, are often downgraded in price throughout the sale chain, from grower to exporter. For example, in the U.S. Pacific Northwest, lots with falling numbers in the 250–300 s range may be discounted $0.25/bu, and those falling below 250 s may be turned away altogether.

Because boiling water is used as the immersion medium for the test tube containing the meal–water mixture, the falling number procedure is affected by the prevailing barometric pressure. As a first approximation, the boiling point of water drops by 1 degree Celsius for every 1,000 ft in land elevation as the air becomes thinner and thinner. The lower boiling point reduces the rate of heat transfer from the water bath through the test tube wall, with the result being a lengthening in the time needed for the stirrer to descend through the heated paste. Consequently, falling numbers collected at an elevator at 3,000 ft, for example, may be more than 30 units greater than those at the export terminal at sea level (where contracts are enforced) unless a correction is applied. The last time a correction function was developed was more than 20 years ago (3,4). Since that time hardware improvements have occurred, and weather patterns in the U.S. Pacific Northwest in recent years (e.g., 2016) have caused a combination of preharvest sprouting and late-maturity amylase: two biochemical conditions that result in elevated alpha-amylase. This has necessitated a greater amount of falling number testing at the margins. Associated with more testing has been a closer scrutiny of the correction function. In summer 2017, at the joint request of the U.S. Federal Grain Inspection Service (FGIS) and the Washington Grain Commission, a study was conducted by the U.S. Department of Agriculture (USDA) Agricultural Research Service to reexamine the correction (2).

The New Correction Model

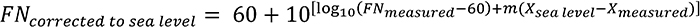

Twelve U.S.-grown wheat samples supplied by the USDA-FGIS, and representing hard red winter, hard red spring, and soft white classes, were repeatedly tested at five barometric pressures corresponding to an elevation range of 0 to 5,000 ft. First-order polynomial linear regression equations were developed based on logarithm-transformed falling number readings (as-is moisture) for each sample to correct non-sea level readings to sea level conditions represented in units of barometric pressure, elevation, or water-bath boiling temperature. Upon finding consistent response behavior among the samples, a universal correction model was chosen:

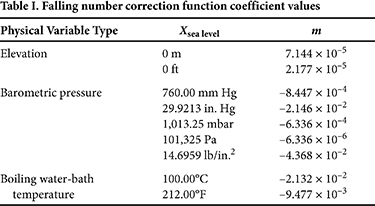

where FN is falling number (s) and X is the physical variable that varies with elevation, be it elevation itself (m, ft), barometric pressure (mm Hg, in. Hg, mbar, Pa), or temperature of the boiling water reservoir (°C, °F). The values of the slope term (m) for the various forms of the physical variable are listed in Table I.

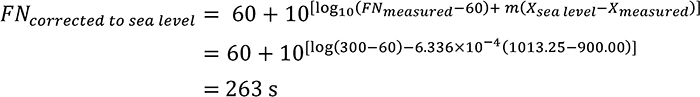

The following is an example of a falling number corrected to sea level conditions. Given a barometric pressure of 900.00 mbar and a corresponding falling number reading of 300 s, then

Features of the New Correction

- Applicable as a correction to barometric pressure, land elevation, or water boiling point, with respective values listed in Table I.

- Continuous function; it may be applied to any elevation between sea level and 5,000 ft.

- Applicable to hard and soft wheat.

- One coefficient; because this coefficient is the slope of a line, the coefficient can be applied using a reference elevation (0–5,000 ft) other than sea level (e.g., correction to a central laboratory at 1,000 ft).

Evaluating the Correction Function

The correction function was tested on a historic set of more than 2,000 commercial wheat samples collected and tested by the USDA-FGIS at 23 field locations ranging in elevation from 0 to 3,300 ft over a 4 year period (2). With application of the correction function, the difference between field location and central laboratory readings, when compared to uncorrected readings, had a reduction in variance of 77%.

Implementing the Correction

The AACC International Approved Methods program (http://methods.aaccnet.org) is the repository for the association’s collection of tried-and-tested procedures on cereals analysis. Each approved method is developed by a committee of professional scientists and undergoes a minimum of two levels of review and voting before reaching “approved” status. Periodically, all methods are reviewed for continuing need, as well as availability of reagents and equipment. The 11th edition of the AACCI Approved Methods of Analysis is the most current version. Between edition releases, a method may be updated by adding a “Note” at its end. The falling number correction described herein is currently being added as a Note to the method bearing its name, “Determination of Falling Number,” Method 56-81.03 (1).